Sign up for our newsletter to stay up to date with

the latest HFLOR/HIMACS design trends and news.

GREEN MANAGEMENT WORKSITES

Green worksites

- Reduce GHG emissions and energy consumption

- Reduce the emission of air pollutants and the use of resources

- Operate a green management system

Expansion of New Green Products and Operations

- Reduce GHG emissions and energy consumption

- Reduce the emission of air pollutants and the use of resources

- Operate a green management system

LONG-TERM GOALS AND PLANS

In accordance with the 3rd planning period of the emission trading system (2021-25), the free allocation rate has decreased from 97% to 90%. Therefore, in 2021, we plan to reduce emissions by approximately 6,800 tons via low NOx burners and improvements made to the pumping of cooling water. We also plan to trade allowances in the market, in the case of excess or shortage of allowances, through quarterly monitoring emissions.

Energy-saving Workplace

- GHG emissions and energy usage reduction activities

- Improvement of old facilities

- Activities aimed at enhancing the use of energy in everyday life

- Reducing the proportion of fossil energy use

Energy-saving Workplace

- GHG emissions and energy usage reduction activities

- Improvement of old facilities

- Activities aimed at enhancing the use of energy in everyday life

- Reducing the proportion of fossil energy use

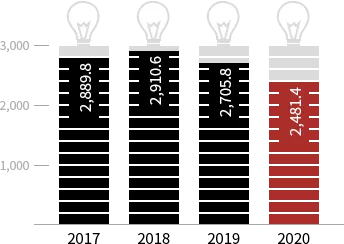

(Unit : TJ)

Energy Consumption

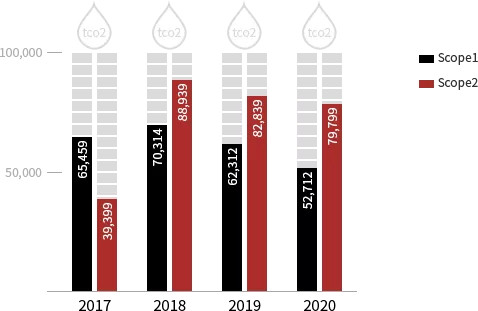

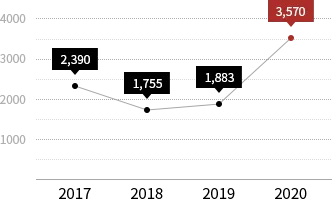

(Unit : tCO2eq)

GHG Emissions

Greenhouse Gas Reduction Activities and Achievements

Innovative Processes and Optimized Operations

We reduce energy usage through innovative processes and optimized operations, and reduce energy costs and greenhouse gas emissions by using external heat sources. In an effort to reduce greenhouse gas emissions and the energy used throughout the production process, our Ulsan Plant is implementing the independent operation of an RTO*, replacement of RTO thermal storage materials, and improvement of the heat boiler supply system. Furthermore, our Cheongju Plant reduces and improves energy consumption during each process, and monitors and performs energy-saving activities such as the application of high-efficiency inverter fans, the installation of high-efficiency refrigerators, and, during winter, turning off air conditioners which control the temperature via outside air.

Substituting Process Raw Materials and Investment in New Facilities

Our Ulsan Plant has successfully reduced volatile organic compound (VOC) emissions from emission facilities when working with water-based treatment agents by replacing some of the process raw materials from oil-based treatment agents with water-based treatment agents. In order to reduce the amount of RTO fuel (LNG) used during the final treatment of the reduced VOCS, the plant changed the operating temperature from 800℃ to 100℃, which is expected to result in approximately a 240,000m3 reduction of LNG per year. The Ulsan Plant also saved KRW 130 million on fuel costs per year by changing the existing RTO into a 3-bed type RTO with improved heat storage material in the furnace, thereby increasing the heat recovery rate from about 86% to 93%.

Introducing Electric Forklifts at our Distribution Center

In 2020, LX Hausys built the Uiwang Distribution Center in order to strengthen our logistics operations, and we are using only electric forklifts to conduct our logistics operations at the distribution center. We actively participate in the government's climate change policy by reducing carbon dioxide emissions through the use of electric forklifts, and we are also considering introducing electric forklifts at our Cheonan and Jincheon distribution centers in the future.

Use of Renewable Energy

In order to further reduce energy consumption, LX Hausys installed and are currently operating solar power generation facilities. Our Cheongju Plant has been operating solar power generation facilities with a total power generation capacity of 3.12 KW since 2013, reducing energy consumption by an average of 1.97tCO2 annually. Our Ulsan Plant is planning to operate a solar power generation facility with a total power generation capacity of 943.8KW from 2024, and is expected to reduce the amount of energy consumed by about 600tCO2 per year. Going forward, in addition to the operation of solar power generation facilities, we will continue to develop various methods that can be applied in order to replace non-renewable energy

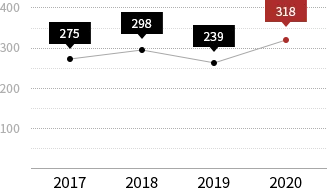

(Unit : TJ)

Reduction in Energy Use

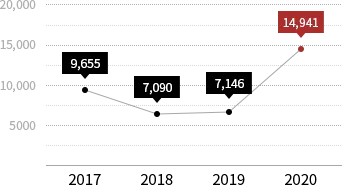

(Unit : tCO2eq)

Reduction in GHG Emissions

(Unit : KRW 1millon)